Cyclone separation and recovery for overspraying powders is widely accepted in the powder coating industry due to its excellent advantages of simple structure, no moving parts, efficient separation and moderate pressure reduction, especially tolerates in high temperature, high pressure and high dust concentration.

As we know, there are two types of cyclone recovery systems configured for automatic powder coating booth, which are mono-cyclone and multi-cyclone. But I believe some of you will be confused which one is better or appropriate. This artical gonna gives you some clues.

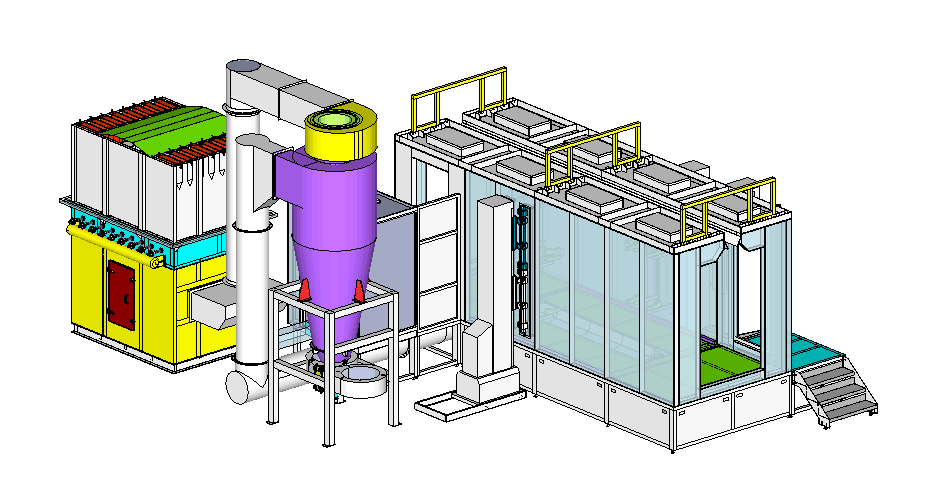

Mono-cyclone Features

It is a single large cyclone, which separates powder from air stream for the principle of centrifugal sedimentation. The heavier particles in the air fall down into a collection tray, while the rest light particles are propelled upwards to a after-filter section. As it is a single cylone it is buit at least 5 meter high, thus your factory should have enough height.

Multi-cyclone Features

Multi-cyclone consists of many small-diameter cyclone tubes to form a whole. It’s separation efficiency is better than Mono-cyclone separator when handle the same amount of airflow, especially capable for collecting fine powders. However, air distribution to each cyclone tube is difficult to be uniform, the recovery performance is not as good as a single cyclone

In conclusion

Mono-cyclone powder coating booth: Easy to clean, Initial choice for quick color change, but requires factory size heigher than 5 meter, and hard to capture fine powder particles.

Multi-cyclone powder coating booth: Capable to handle fine particles, requires lower factory height and small CFM, but not as easy cleaning as mono-cyclone.